MP UV Disinfection System

What is MP UV Disinfection System?

MP UV disinfection system uses medium pressure lamps with a polychromatic output from 180-400nm wavelength, specifically enhanced to have broad band germicidal properties.

MP UV disinfection system uses medium pressure lamps with a polychromatic output from 180-400nm wavelength, specifically enhanced to have broad band germicidal properties.

LP UV Lamp

|

MP UV Lamp

|

|

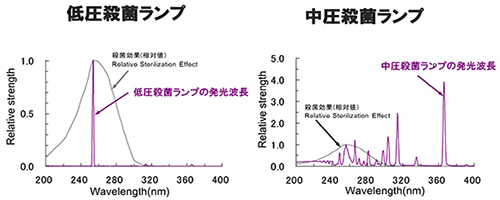

1.Wavelength Features Difference

LP UV Lamp:Bactericidal wavelength unvarying; centralized around 254nm.Microorganisms themselves possess regenerating mechanisms, some that are killed under UV rays may still resuscitate,resulting in a failure for effluent microorganisms to meet standards.

MP UV Lamp:Broad-spectrum sterilization; medium pressure lamp can emit light with a wavelength of 365nm. Experiments have proved that light with a wavelength of 365nm can drastically suppress photoreactivation, and reach a more complete sterilization. Toshiba’s research on this topic won the “Best Paper Award” at the at the Lux Pacifica, Pacific Basin Lighting Congress. |

|

|

|

|

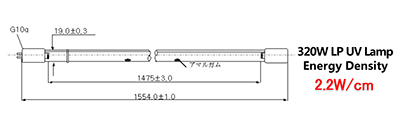

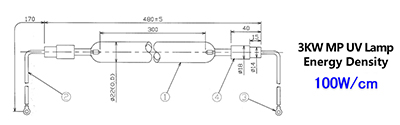

2.Energy Density Difference

The energy density of medium pressure lamps per unit centimeter is fifty times that of low pressure lamps, guaranteeing a powerful bactericidal effect while tremendously lowering the equipment’s area.

Many customers used low pressure UV devices, which yielded satisfying effects after immediate use, but were perplexed when the bacteria level exceeded standards after a few days. After replacing it with our medium pressure UV device, they were well-satisfied. |

|

|

|

|

1.Imported Toshiba light source, developed specifically for water treatment, stable and reliable function

Imported Toshiba light source, developed specifically for water treatment, stable and reliable function.Because medium pressure UV lamps have a complex production process that has high technical requirements, our domestic products have only a life of one thousand hours. And its luminance drops distinctly, with unstable sterilization.

Toshiba’s medium pressure UV lamp is specially developed for water treatment. After 7500 hours of live lighting tests, they still perserve a 82.6% luminance maintenance rate, surpassing other international brands.

|

|||||

Toshiba UV lamp factory

|

Towin visiting Toshiba

|

||||

|

2.Scientific design guarantees effective UV dose

It is important that the designs varies with different water bodies treated, or else the designated bactericidal effect would not be reached. Towin partnered with Toshiba UV electrics & optics department and guarantees our scientific design meets its effects.

|

|||||

Illuminance Maintenance Rate Contrast Map

|

Toshiba Technician Experiment Site

|

||||

|

3.High cost-effective production

Using Toshiba’s core UV technology and localization equipment production, improving step by step, we achieve the goal of introducing products of high performance produced at low cost.

|

|||||

Domestic UV Equipment Processing Factory

|

|||||

|

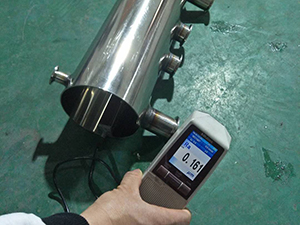

4.Continuously perfecting the production process

Medium pressure UV lamps can reach a 800 degree celsius surface temperature, far exceeding that of low pressure UV lamps. This sets forth a high demand for the equipment’s safety and tightness. Towin has been focusing on UV-ray applications and continuously perfecting the production process to assure our customers.

|

|||||

|

|

|

|

①Testing on UV luminance and temperature , acquiring first-hand data;

②Water pressure test before leaving the factory , assuring product’s safety; ③Cavity polishing Ra level 0.161μm , far below the medicine factory requirement of 0.5μm. |

||

|

|

|

|

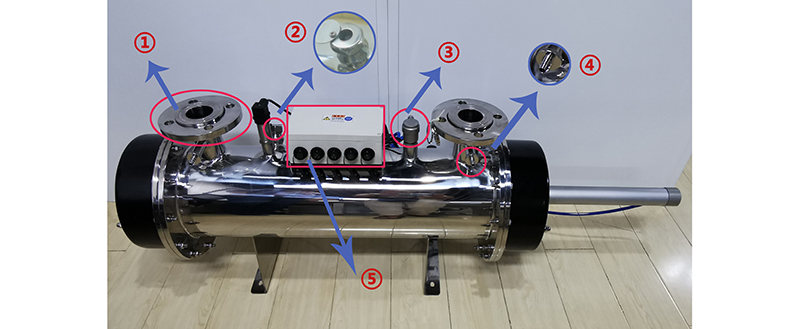

①Toshiba Medium Pressure UV Lamps:Polychromatic wavelength UV output to ensure an effective disinfection without the photoreactivation.

②Stainless Steel UV Reactor:Utilize CFD system to fully consider the hydrodynamics and inside polish treatment to enhance the disinfection efficiency.

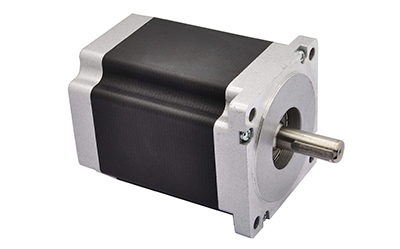

③Full Automated Wiper Cleaning System:Full automated wiper cleaning system to avoid quartz sleeve fouled to ensure the effective disinfection.

|

||

|

|

|

|

④UV Intensity Monitor:A UV monitor onboard is used to provide real time and auditable records of UV intensity.

⑤Temperature Sensor:A temperature sensor is installed online to ensure a reliable and safe operation with alarm for high temp limited level and power cut off.

⑥Automated Control System:The control system provides stable power output,real time UV intensity monitor, and recorder of operation time and temperature.

|

||

|

||

|

①Rotating flanges: it is easy to install and dismantle when connect with the other pipe;

②Lens: more safe and pretty of rotating light shield;

③Auto exhaust valve: automatic discharge of air in the reactor;

④Sampling port: before and after disinfection data are more accurate which get sample from in and out of the water port with sampling port;

⑤Connection box: waterproof type connector, easy installation and safety.

|

||

|

|

|

|

aquaculture

|

aquaculture

|

cooling water

|

|

|

|

|

bottled water

|

Micro-algae

|

pool water

|

|

|

|

|

|

|

|

|